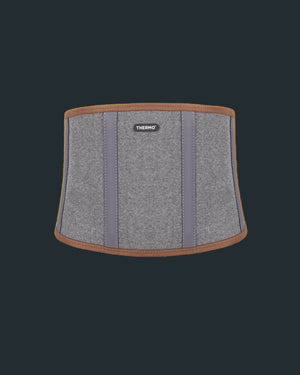

Recovery wear is crucial for many. It can be used to greatly reduce chronic pain, soothe the pain that comes from intense exercise and athleticism, and encourage e...

Recovery wear is crucial for many. It can be used to greatly reduce chronic pain, soothe the pain that comes from intense exercise and athleticism, and encourage early recovery for a variety of issues.

However, there’s something else that has to be thought of while we try to cure our own ailments. The environment.

Luckily, there have been a number of innovations in recovery wear production that make it good for you and good for the environment.

Here are some of the best ways we’re making sustainable recovery wear at Thermo Recovery Wear and the industry standards that are starting to take shape.

1: Reusing Textiles

Athletic recovery wear is extremely advanced, but at its core, it’s still part of the clothing industry, and just like t-shirts, pants, and every other type of clothing item you can imagine, it’s completely dependent on textiles.

Textiles are essentially large supplies of fabric that is used in the production of an athletic recovery wear piece. Each piece of the item is cut from the textile and stitched into the product you know and love.

Well, unfortunately, you can never use the entirety of the textile. Patterns simply don’t use up every little scrap.

However, the textiles can be reused to either be recycled into new full textiles, turned into another product, etc.

This ensures that the remaining pieces of textiles are used instead of being tossed in the bin. The textiles don’t even have to be used within the same company. Used textile pieces can be used by other industries for a variety of products and recycling purposes.

2: Inventory Management

Inventory management is crucial for any business that wants to stay afloat. So, this is important even beyond the sustainable recovery wear industry. However, while inventory management can help save money and keep productivity moving smoothly, it’s also an eco-friendly advancement.

When a manufacturer is capable of knowing exactly how much material is in stock, how much a production run is going to require, and how much it’s going to need to fully complete a run, it can minimize the amount of material purchased.

This means that there isn’t a surplus of materials that end up sitting around for ages and eventually getting tossed out.

This can be a big problem in any part of the textile industry. If too much material is purchased for a production run, that run is completed with lots of leftovers, and there’s no need to do another run for a while, the material can end up damaged or needing to be removed to make space for more immediate priorities, and it is all waste.

It wastes the energy used to manufacture the material, and then it leads to the material ending up in a landfill.

Proper inventory management can save money and help the environment, and it should be a priority for every business.

3: Waste Reduction in Manufacturing

Textiles aren’t the only things that generate a lot of waste in a manufacturing environment. Plenty of other things do, too.

There are all the little pieces of PPE, packaging, and similar items that staff members have to use as part of their job. While they’re necessary, they generate lots of waste in manufacturing environments.

Since those things are necessary when producing recovery wear, they can’t just be phased out. There will always be trash generated by switching out PPE, getting materials out of packaging, or even just enjoying lunch breaks.

To combat this, major strides are made to reduce that waste by simply adjusting company policies, resources, and sourcing options.

For example, production management limits how many tasks a single worker is taking on, and that allows them to keep using the same PPE for the majority of their shift, recycling receptacles are available, and the way trash is discarded from the production facilities themselves is adjusted to ensure as much is being reused as possible.

4: Leveraging Tech to Reduce Our Impact on the World

As a provider of therapeutic products, we obviously want to make the biggest impact we can on the world, but only in that regard. When it comes to the negative impact we have on our communities and natural environment, that’s something we want to shrink as much as possible.

Thankfully, it doesn’t all come down to policies that reduce waste or innovative ways to use materials. Not everyone in the industry does this, but it is a growing standard.

Tech can be used to limit waste, emissions, and resource consumption extremely effectively.

This can include small technological advances such as using more solar power than fossil-fuel-based power and purchasing necessary backbone equipment such as computers that aren’t energy hogs.

It can also include major parts of the industry such as investing in manufacturing equipment that uses a fraction of the resources and emissions of traditional equipment.

Tech is a huge part of the recovery wear industry in all phases, and by leveraging the latest eco-friendly tech, we can make a massive difference.

5: Using Sustainable Materials

Earlier, we mentioned recycling textiles or sending the scraps to companies that can use them for other purposes, but it’s not enough to just ensure fresh textiles are used optimally.

With so many recycling methods available on the market, and new materials being developed all the time, another major innovation is ensuring that each material used in production is from a sustainable source.

This includes using textiles made from sustainable plant material or recycled fabrics, making the switch to eco-friendly versions of the basic essentials any business uses throughout the day, and partnering with suppliers and similar entities that value sustainability, as well.

Recover from Chronic Pain and Help the World Recover with Thermo Wear

At Thermo Wear, we value sustainable business practices and strive to ensure that our products cause as little negative impact as possible. We also produce cutting-edge sustainable recovery wear that reduces inflammation and pain without medications, therapies, or anything like that.

To recover your body and the world, shop at Thermo Recovery Wear.